Rosettes

Overview

|

Rosettes are cams, and they are used to produce the rocking or pumping actions needed on rose engine lathes. The rosette is truly what makes the magic happen.

Typically, rosettes with the patterns on the edge (like those shown below on the left) are used to produce rocking action, and rosettes with the patterns on the face (side) are used for pumping action.

It is now common to see rosettes which have phasing holes pre-drilled in them, removing the need for a crossing wheel. The advantage noted for using the phrasing holes in the rosette is that it takes a lot of the math out of the process as you don't have to calculate how much to move the crossing wheel to achieve the phasing you want.

Additionally, you are provided phasing outcomes which would be difficult to do otherwise (i.e., phasing a 7-lobed rosetted by half a lobe is difficult when 25.7° of rotation is needed.

Lastly, each rosette can be phased relative to another rosette, not just the object.

Rosette with Phasing Holes

Image courtesy

OrnamentalRoseEngine.com

This opens up a whole new set of artistic options for the ornamental turner, AND will give more abilities to stay out of your spouse's way when you retire!

This is the approach that Jon Magill has purposefully taken with the design of the MDF Rose Engine.

Note: an indexing wheel could also be used to phase the rosettes, and that is how I made my first rose engine lathe. But an indexing wheel this small usually only has 5° increments, and that is cumbersome for rosettes with lobes that are not increments of 5°. And even when the increments are divisible by 5, the actual use of this approach is tedious and mistakes are easy to make ("Did I advance it 4 holes or 5?"). This is why machinists typically use an indexing wheel with stops so that each advance is equal.

Additional pictures of this device

Examples of this device in use

- In this YouTube Video, Wes Pilley describes how he turns the petals on a Tudor rose on his Lindow rose engine lathe.

- This YouTube Video shows the beauty of rosettes in motion.

- This YouTube Video shows a horizontal cutting frame cutting on the far side of the rosette (around 5:33 into the video). At the end, you can see the clover leaf design produced.

- Al Collins is one of the current day masters on the rose engine lathe, and this YouTube Video of his machine, showing rose engine turning with a ridiculously complicated, 3D rosette! I am pretty sure there are less than 10 people in the world who can make something like this, and only a handful more who know how to use it.

Usage Notes

One of the really cool things about rosettes is that the piece can be made very differently using the various options with the given rosette on the rose engine lathe. For example:

- Positioning the cutting frame so that it cuts on the near side of the piece makes the typically expected design.

- Positioning the cutting frame so that it cuts on the far side of the piece makes an inverse of the rosette.

- The shape of the rubber can change the shape of the piece made. Eddie Bell gave a presentation about this the 2018 Ornamental Turners International Symposium, and you can watch that video on the rubbers page in this dictionary.

Lotus 8 Rosette

- Moving the cutter towards the center, or away from it, certainly changes what happens with the resultant shape. A rosette is designed for a certain size diameter, and cutting at a different one will make the shape change.

- Fading can also be employed to produce shape changes. (That page in this site has a video outlining how it works.)

- Using two rosettes (with separate rubbers for each) can produce some shapes which are really amazing. The pictures below show paper chuck drawings for two rosettes (a P-4 and an A-24) and a piece which was made using these together. The A24 rosette paper chuck drawing is from Holtzapffel's booklet, The Rose Cutting Frame, where the colors are reversed from what I've produced.

Plain 4 Rosette |

+ |

A-24 Rosette |

= |

|

|

|

|

Rosettes to Start With

Not all rosette manufacturers follow the Holtzapffel scheme in labelling what they make, but they follow a similar scheme. And, there have been rosette shapes made since that time that follow their own naming convention.

My recommendation is to start with one of each of these rosettes,

- Holtzapffel A series : sine wave, maybe a A-24

- P series : plain polygon rosettes, maybe a P-4

and then move on to more complicated ones as you grow your skills and your understanding of where you want to go with the craft.

|

|

|

Usage Hint

John Calver sent an idea in to the Rose Engine News (Volume 4, No. 1 - Spring-Summer, 2013, pg, 19):

Notes on making rosettes

Ornamental turners can make their own rosettes; however that requires :

- Strong knowledge of how to make rosettes which achieve the desired result. Some recommendations for learning more are:

- Charles Marie de la Condamine's papers presented to the Royal Academy of Sciences (in French, by the way)

- Paul L. Ferraglio's translations of M. de la Condamine's papers (1975)

- Books by Louis-Eloi Bergeron (1796 -- also in French)

- Norman Tweedle's translation of Bergeron's book (1950)

- Martin Matthews' translation of Bergeron's book (1984)

- Jeremy Soulsby's translation of Bergeron's book (2010 - available from the Society of Ornamental Turners)

- Society of Ornamental Turners' Bulletins #46 and #52

- Charles Marie de la Condamine's papers presented to the Royal Academy of Sciences (in French, by the way)

- Software to design the rosette

- CNC-driven milling machine to cut the rosette

This YouTube video is about the history, design, and production of rosettes. It was given by Jon Magill at the 2018 Ornamental Turners International Symposium. As you will probably note, this is not for the faint of heart. He lost me when he discussed Rectangular Lissajous Curves.

It is cheaper (and a whole lot faster) to buy pre-made rosettes than to learn how to design a rosette, and acquire a CNC milling machine. But, if you are seeking a reason to buy (and learn to use) a CNC milling machine, this is as good a reason as any. And, you can make rosettes that are very special-purpose in nature (Jon Magill designed a rosette which produces shamrocks -- very cool!).

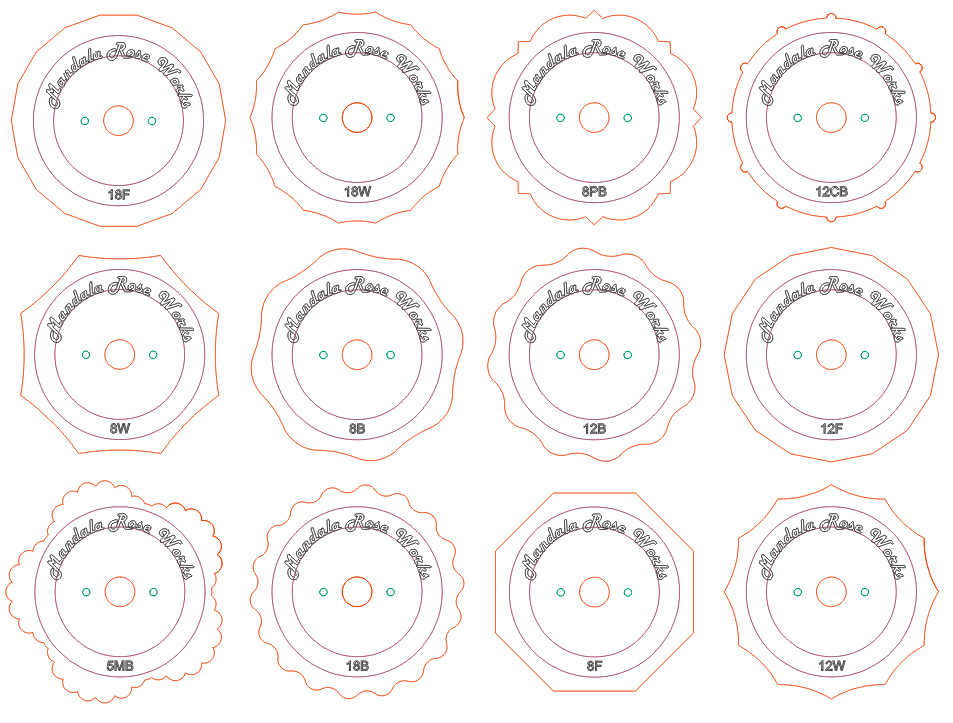

I purchased acrylic rosettes from Mandala Rose Works (for the rose engine lathe I made from a Delta Midi lathe).

HDPE rosettes are commonly used on the MDF Rose Engine Lathe, thought various other plastics, including Corian, are also used. Of course, the ornamental turner could always go old school and buy brass rosettes.

|

|

|

Making Rosettes from Other Rosettes

|

+ |

|

= |

|

It is common for a rose engine user to make a new rosette on their rose engine lathe, using two other rosettes as the basis for that design. This new rosette then becomes the combination of the other two. An example is to the right.

|

|

|

3D Printing Rosettes

Ian Lane published an article titled, "Rosette Design and Fabrication" in the The Society of Ornamental Turners' Bulletin #145, Spring 2022. That article outlines his use of OpenSCAD to design a rosette for 3D printing.

Colin Spencer published an update to Ian's article titled "Rosette Design and Fabrication Part 2", in the The Society of Ornamental Turners' Bulletin #147, Autumn 2022. Colin used FreeCAD to design rosettes, gears, and rubbers. These were then printed on his Ender 3 V2 printer.

The web site, TurnLincs.com, outlines the Colin Spencer's "Home-made Rose Engine Lathe". The author also provides the designs for the rosettes he has crafted. This is the link for the STL files. As he notes, "each of the rosettes is 150mm in diameter with a 14mm central hole and the phasing holes are 50mm from the centre and 3mm in diameter. These can be printed in PLA on a 3D printer."

Sources for buying rosettes

- Lindow Rose Engine - Lindow Machine Works

- MDF Rose Engine - Colvin Tools

- Other - Colin Spencer will work with you to develop rosettes for your need, and also to 3D print them. You will need to contact him via the "Contact Me" link on his web page, turnlincs.com/rosettes

More Information

Published Articles

- A Caddy to Safely Hold Rosettes by Charles Waggoner. OTI Newsletter, Volume 21, No. 2 - Summer, 2014, pg. 19

- Changing Rosettes on a L-W Rose Engine by Brian Clarry LW Rose Engine News, Volume 2, No. 2 - Autumn-Winter, 2011, pg. 6

- A Geometric Cam Generator by Al Collins. OTI Newsletter, Volume 15, No. 3 - Winter, 2008, pg. 8

- Cam (Rosette) Fundamentals, with Emphasis on Ornamental Lathe and Rose Engine Applications, by Vern West. OTI Newsletter, Volume 21, No. 1 - Spring, 2014, pg. 21

- Lindow Rose Engine Alignment Procedures, Section 1, pg. 7

- Lindow Rosettes by (unknown). Rose Engine News, Volume 6, No. 1, Spring-Summer, 2015, pg, 6.

- Of Rubbers and Rosettes by David Lindow Rose Engine News, Volume 3, No. 1 - Spring-Summer, 2012, pg, 10.

- Patterns and Phasing by John Tarpley. Rose Engine News, Volume 5, No. 1, Spring-Summer, 2014, pg, 12.

- Patterns On Side Grain Produced From Sine Waves by John Tarpley. Rose Engine News, Volume 4, No. 1 - Spring-Summer, 2013, pg, 20.

- Rosette-Cutting Jig by Doug Ryan. OTI Newsletter, Volume 15, No. 3 - Winter, 2008, pg. 4

- Rosette Design and Fabrication by Ian Lane. The Society of Ornamental Turners Bulletin #145, Spring 2022, pg. 14.

- Rosette Design and Fabrication Part 2 by Ian Lane. The Society of Ornamental Turners Bulletin #147, Autumn 2022, pg. 22.

- Rosette Iterations: Going Round and Round by Michael J. Ezzo. Rose Engine News, Volume 5, No. 2, Fall-Winter, 2014-15, pg, 25.

- Rosettes by John Tarpley. Rose Engine News, Volume 3, No. 1 - Spring-Summer, 2012, pg, 3.

- Rosettes by (unknown). Rose Engine News, Volume 4, No. 2, Tool Bonus Issue, 2014, pg, 3.

- Rosette Storage by John Tarpley. Rose Engine News, Volume 4, No. 1 - Spring-Summer, 2013, pg, 4.

Books and Papers

- Charles Marie de la Condamine's papers presented to the Royal Academy of Sciences

- Paul L. Ferraglio's translations of M. de la Condamine's papers (1975)

- Jeremy Soulsby's 2010 translation of Louis-Eloi Bergeron's book, Manuel du Tourneur (available from the Society of Ornamental Turners)

- Society of Ornamental Turners' Bulletin #46

- Society of Ornamental Turners' Bulletin #52

|

Holtzapffel Rosettes  F-4  A-12  D-12 |

Web Sites

- Holtzapffel was probably the first to put a structure in place for how rosettes are named, and the Holtzapffel company made a machine for making them (today, most manufacturers use CNC-driven milling machines).

- F-1 is used to produce a heart shape

- F-2 would probably not work well as it would be hard to lay the shapes out around the perimeter in a way that would make a pleasing shape, and the amplitude change might be too large.

- F-4 is where it begins to work again, and you end up with a shape like in the picture to the right.

- Colin Spencer has published the 3D CAD files (STL format) for the rosettes he created. They are at TurnLincs.com/rosettes.

|

Disclaimer: eMail comments to me at OTBookOfKnowledge @ Gmail.com. The process of woodturning involves the use of tools, machinery and materials which could cause injury or be a health hazard unless proper precautions are taken, including the wearing of appropriate protective equipment. |